What are Discrete Analysers?

How Discrete Analysers Work: A Guide to Automated Chemical Analysis

Discrete analysers are widely used in laboratories across industries for automated chemical analysis of liquid samples. Whether you're testing water quality, environmental samples, monitoring wine and beverages, or analysing food and feed products, these instruments deliver fast, precise, and high-throughput results. But how do they actually work?

In this article, we’ll break down the key components and working principles of a discrete analyser, and why they're a powerful tool for modern laboratories.

A discrete analyser is an automated laboratory instrument designed to perform chemical analyses on liquid samples. Unlike continuous flow analysers (which process samples in a stream), discrete analysers treat each sample independently in its own reaction vessel (such as a cuvette).

This discrete handling allows for greater flexibility, reduced cross-contamination, and simultaneous testing of multiple analytes.

Key Components of a Discrete Analyser

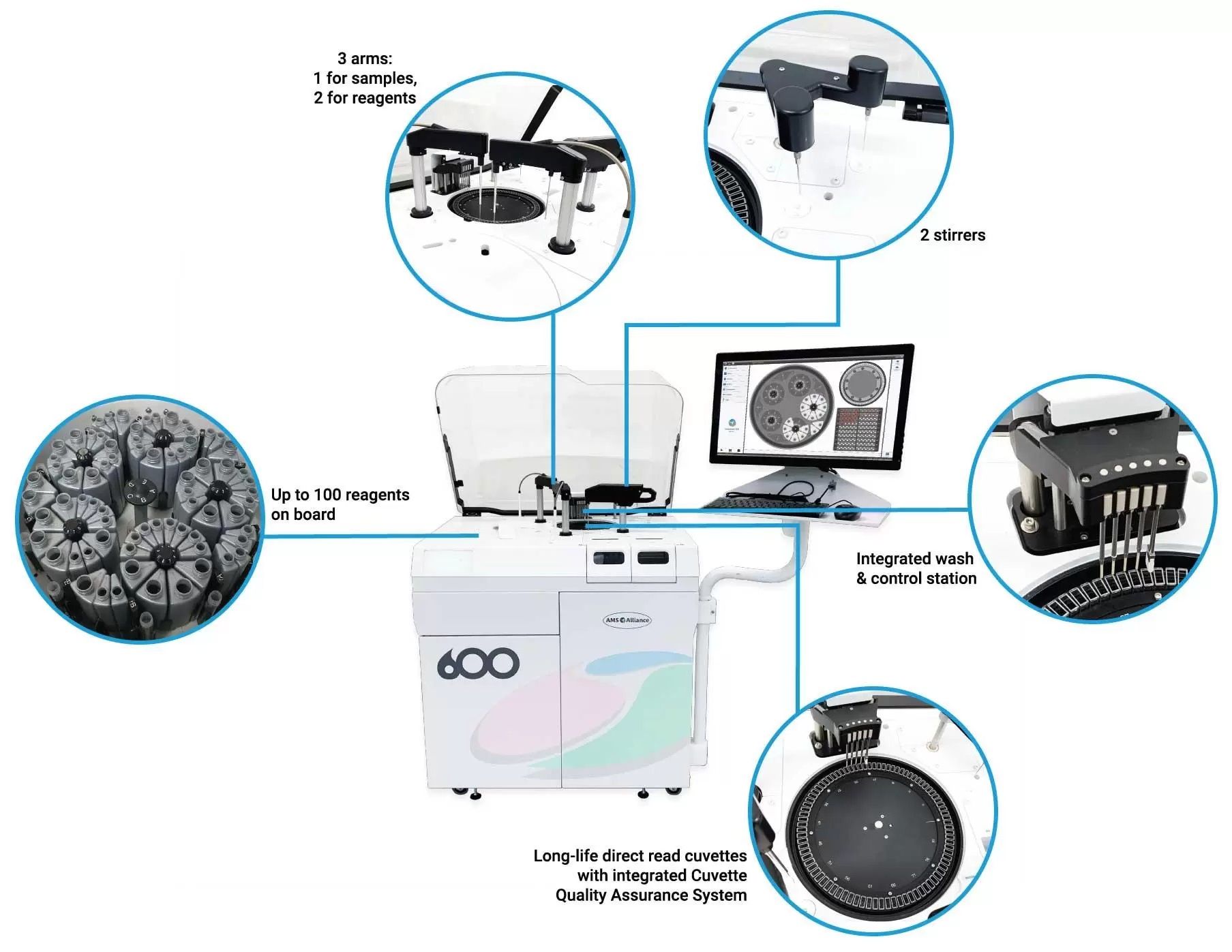

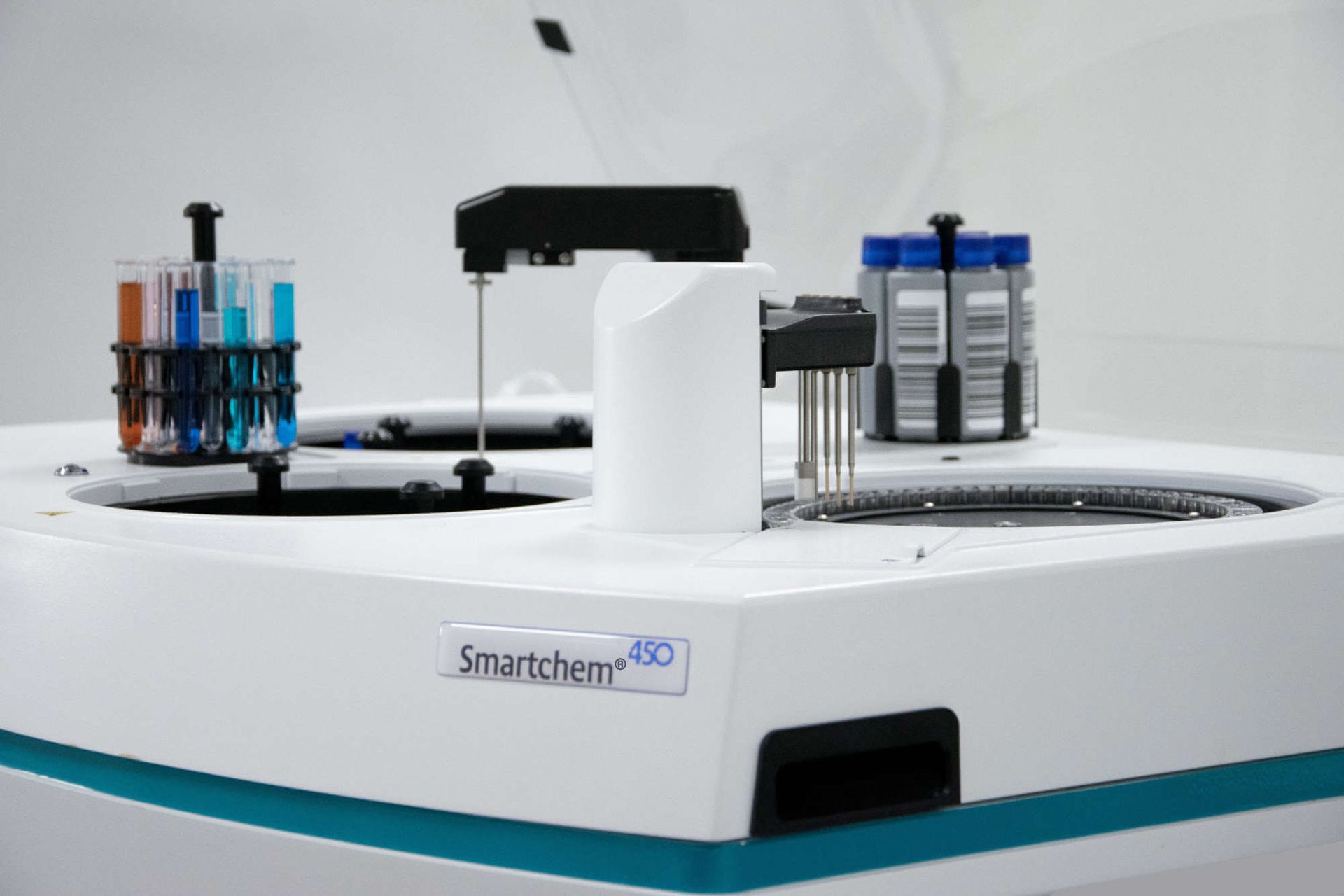

- Sample Tray

Holds tubes containing the liquid samples to be analysed. The instrument automatically selects each sample in sequence. - Reagent Tray

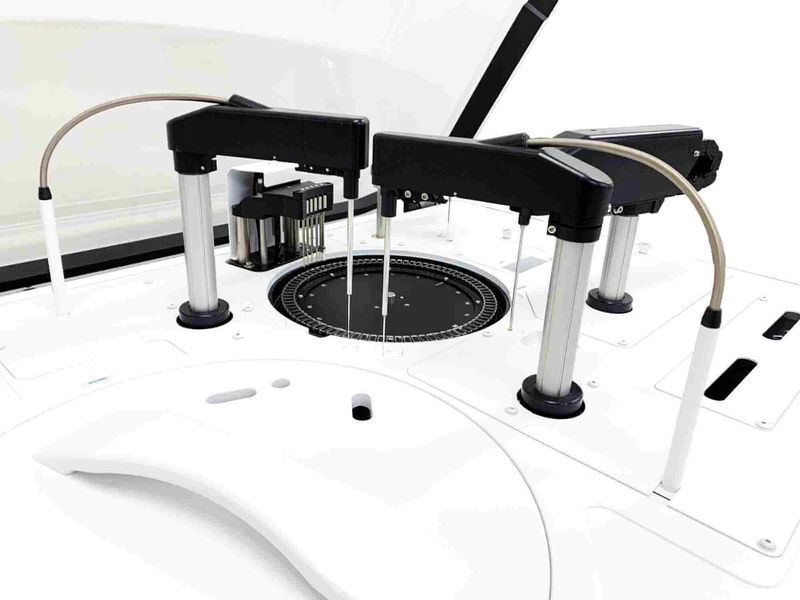

Contains bottles of chemical reagents required for the analytical reactions. The system can use multiple reagents per test, depending on the method. - Dispensing System

A robotic arm mechanism precisely dispenses sample and reagent volumes into reaction cuvettes. - Reaction Plate

This is where the chemical reactions occur. Each cuvette is isolated, allowing independent timing and temperature control. Maintains constant temperatures for consistency and stability . - Photometric Detector

Measures the absorbance or optical density of the resulting reaction, typically using spectrophotometry. The intensity of the colour change correlates with the concentration of the analyte. - Software Interface

Controls the analyser’s operations, stores calibration data, manages QC protocols, and processes final results.

How a Discrete Analyser Works (Step-by-Step)

- Sample and Reagent Loading

The user loads the samples and reagents into their respective trays. The software assigns each test according to the method and sample ID. - Dispensing and Mixing

The robotic arms aspirate a precise volume of sample and reagent, dispenses them into a reaction cuvette, and mixes them. - Incubation

The reaction is incubated for a specific time, allowing the chemistry to develop. Enzymatic or colorimetric reactions are common. - Measurement

Once the reaction is complete, the system reads the absorbance using a photometric detector. Different wavelengths may be used depending on the assay. - Result Calculation

The software compares the absorbance to calibration curves and generates a concentration value for the analyte. - Data Output

Results are saved, printed, or exported to a laboratory information system (LIS/LIMS).

Benefits of Discrete Analysers

- High throughput:

Dozens to hundreds of samples processed per hour

- Flexible testing:

Run different tests on each sample without reconfiguration

- Low reagent use:

Optimised volumes reduce cost per test

- Minimal cross-contamination:

Independent cuvettes and wash steps prevent carryover

- Ease of automation:

Ideal for routine testing in clinical, environmental, or industrial labs

Common Applications

- Water and wastewater analysis (e.g., alkalinity, chloride, sulphate)

- Soil analysis (e.g., nitrite, phosphate, ammonia)

- Beverage testing (e.g., sugar, acid, colour)

- Food and feed testing (e.g., nitrates, nitrites, phosphate)

Summary

Discrete analysers offer a reliable, automated solution for performing chemical analyses efficiently and accurately. Their versatility makes them suitable for a wide range of industries, and their ability to process multiple parameters from minimal sample volumes makes them invaluable in both high-throughput and specialty labs.

If you're considering upgrading your lab's analytical capabilities, a discrete analyser could be a smart investment.